APT50GH120B Datasheet: Complete Specs, Curves & Thermal

APT50GH120B Datasheet: Complete Specs, Curves & Thermal

The APT50GH120B is a 1200 V, 50 A fast field‑stop IGBT optimized for high‑voltage switching where efficiency and thermal resilience dictate device choice. This guide turns the raw datasheet into actionable design inputs—which rows to trust, how to size cooling, and how to read curves—so engineers can size, test, and deploy with confidence.

It covers quick reference fields and early‑stage derating, absolute ratings and SOA, static and dynamic curves, thermal metrics and cooling practice, PCB/module layout guidance, and a practical validation checklist. Primary keywords in use: APT50GH120B, datasheet, specs; designers should focus on the VCES, IC, VCE(sat), thermal resistances, and switching energy curves first.

APT50GH120B: Quick Reference & Background

What this device is and typical package options

Point: The device class is a 1200‑V, 50‑A fast field‑stop IGBT meant for medium‑power conversion. Evidence: Datasheet spec lines show 1200 V blocking and 50 A continuous rating at controlled case conditions. Explanation: Package choice alters RthJC and leadframe current capability, so note whether the part is in a bolt‑down or TO‑style package when estimating thermal coupling and mounting force.

How to use this quick reference in early-stage design

Point: Treat quick‑lookup fields as starting points, not safe operating guarantees. Evidence: Datasheet lists absolute max, test conditions, and pulsed ratings separately. Explanation: Designers should separate 'design‑limits' (derated continuous values) from 'test conditions' (short pulses at TC=25°C), apply temperature derating, and include safety margins for system transients and aging.

Key Electrical Specs & Absolute Ratings

Absolute maximums and safe-operating-area (SOA) highlights

Point: Absolute maxima (VCES, IC pulse, Tj max) define non‑reversible limits. Evidence: Datasheet rows for VCES, IC (continuous/pulse), VGE max, Tj max and transient dv/dt/di/dt thresholds are critical. Explanation: Use TC‑referenced pulse ratings with conservative derating—for example, scale pulse current by 50% for continuous duty and reduce allowable power as junction temperature rises toward Tj max.

| Parameter | Datasheet | Conservative Operating |

|---|---|---|

| VCES (max) | 1200 V | ≤900 V for margin |

| IC (cont) | 50 A | ≤35 A @ elevated T |

| IC (pulse) | specified | use only for |

| VCE(sat) | typ/max at test | allow +20% at Tj↑ |

| Tj max | specified | keep ≤125°C |

Static characteristics to prioritize (DC)

Point: VCE(sat) and leakage define conduction losses and off‑state dissipation. Evidence: VCE(sat) increases with IC and junction temperature; leakage grows exponentially with temperature. Explanation: Validate VCE(sat) at your expected IC and Tj and set pass/fail margins (for example, VCE(sat) ≤ datasheet max ×1.2 at operating T); measure leakage at blocking voltage and elevated temperature to confirm safe standby dissipation.

Characteristic Curves: How to Read & Apply Them

Important curves to extract and what they tell you

Point: Key curves are Vce vs Ic, transfer (Ic vs Vge), SOA, Eon/Eoff vs Ic, and capacitances. Evidence: Each curve includes axes and test conditions (VGE, TC) that limit applicability. Explanation: Always note the test VGE and TC; extrapolating switching energy at different gate drive or temperature requires scaling per the curve trends and conservative margins when data points are sparse.

Practical examples: using curves to size switching components

Point: Combine conduction and switching data to estimate device losses for thermal sizing. Evidence: Use VCE(sat) at operating IC and Eon/Eoff at chosen Vdc and VGE to compute Pd. Explanation: Example workflow: 1) read VCE(sat) at IC and Tj, 2) compute Pd_cond = IC×VCE(sat), 3) read Eon+Eoff per switching event × fsw for Pd_switch, then sum Pd and derive required Rth_ja for acceptable ΔT.

| Input | Value |

|---|---|

| Ic | 30 A |

| Vdc | 600 V |

| fsw | 10 kHz |

Thermal Performance & Cooling Guidelines

Thermal metrics to capture and how to use them

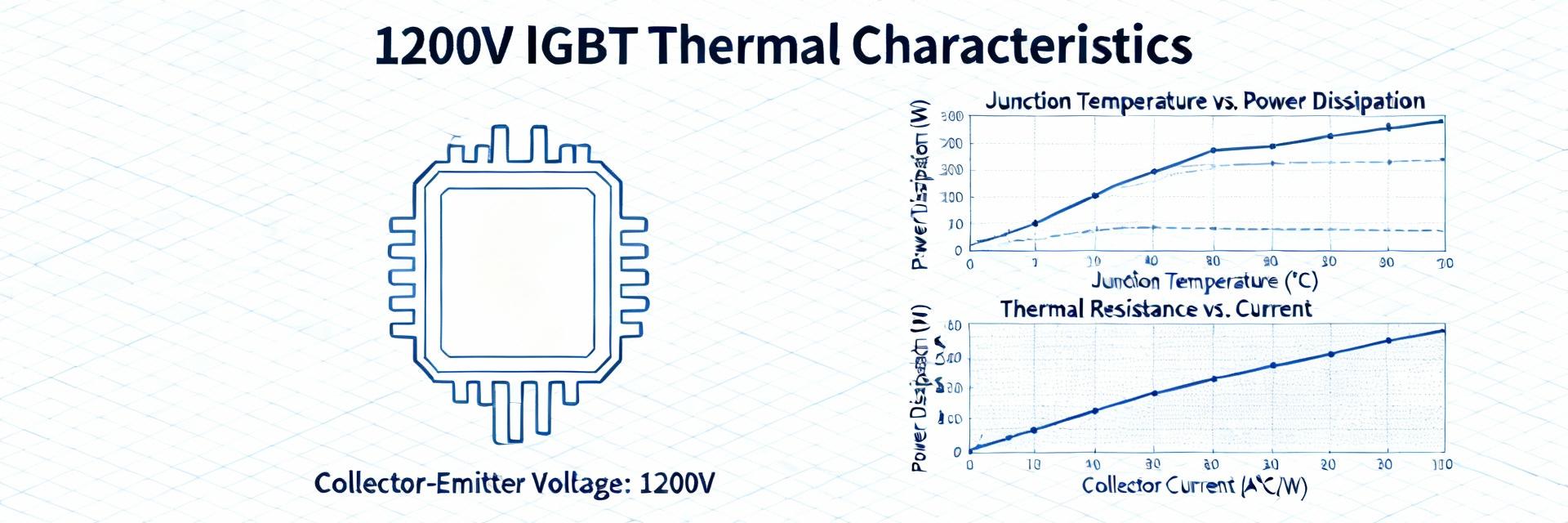

Point: RthJC, RthJA, and transient Zth vs pulse width are mandatory metrics. Evidence: Datasheet thermal plots show temperature rise versus power and pulse duration. Explanation: Convert predicted Pd into allowable ΔT and compute Rth required (Rth = ΔT / Pd). For pulsed operation use the Zth curve at the corresponding pulse width rather than steady Rth values.

Practical cooling strategies and verification

Point: Choose mounting and TIM to minimize thermal resistance; verify with measurement. Evidence: PCB mounting, torque, TIM thickness, and airflow change Rth significantly. Explanation: Use torque spec for bolts, thin controlled TIM layer, and prefer forced air for mid power or liquid for high continuous Pd; verify with steady‑state and pulsed thermal measurements using thermocouple at case and IR imaging on live parts.

Application Examples & PCB / Module Considerations

Typical use-cases and circuit roles

Point: Device fits medium‑power inverters, motor drives, and high‑voltage supplies. Evidence: Key decisive specs are VCES margin, continuous current, switching energy, and SOA. Explanation: Select based on worst‑case blocking voltage, required continuous current at operating temperature, and acceptable switching losses; prioritize SOA for inductive load turn‑on and turn‑off events.

Footprint, layout, and parasitic considerations

Point: Minimize loop inductance and use Kelvin sensing for accurate drive and measurements. Evidence: Gate loop inductance increases overshoot and switching energy; long traces raise di/dt stress. Explanation: Route gate and return close, add local decoupling, place snubber components near device, and select gate resistor values to balance switching loss and dv/dt robustness per energy curves and dv/dt tolerance.

Test, Validation & Design Checklist (Actionable)

Pre-production validation steps

Point: Validate static IV, switching waveforms, and thermal behavior under representative conditions. Evidence: Measure VCE(sat), leakage, Eon/Eoff, and Zth with the same TC and VGE used in the datasheet curves. Explanation: Capture switching waveforms at target Vdc, fsw, and gate drive, run steady‑state thermal tests, and perform power cycling and short‑circuit checks where relevant to verify SOA margins.

Sourcing, reliability notes, and final checklist for deployment

Point: Ensure traceability and handling conform to power‑semiconductor best practice. Evidence: Marking verification, lot traceability, and proper storage protect part integrity. Explanation: Inspect package solder fillets, implement thermal cycling plans, confirm procurement lot identity, and tape/reel or dry storage as recommended to reduce moisture‑related failures before assembly.

Summary

This guide turns the APT50GH120B datasheet into pragmatic steps: capture absolute ratings and derate for continuous use, extract curves to estimate real losses, and validate thermal performance with focused tests. Designers should prioritize blocking voltage margin, thermal budget, and switching energy in early selection decisions to prevent field failures.

- Capture and derate absolute ratings: record VCES, IC, VGE, and Tj max, then apply conservative continuous limits and temperature derating to define safe operating points.

- Use characteristic curves: extract VCE(sat), Eon/Eoff, and SOA plots at relevant TC and VGE to compute conduction and switching losses and size thermal management.

- Verify with focused tests: perform IV, switching energy, steady and pulsed thermal measurements, and short‑circuit checks to confirm margins before production.

FAQ

What are the essential APT50GH120B datasheet rows to record for initial design?

Record VCES, IC continuous and pulse, VCE(sat) at test conditions, VGE(th) and VGE(max), collector leakage vs temperature, Tj max, RthJC/Zth vs pulse width, and Eon/Eoff curves. These rows let engineers compute Pd, required Rth, and SOA margins to size cooling and gate drive accurately.

How should engineers derate pulse ratings from the APT50GH120B datasheet for continuous operation?

Convert pulse to continuous by applying both time and temperature derating: limit pulse‑rated currents to ~50–70% for continuous duty, reduce allowable power with junction temperature rises (use Zth curves to map pulse width), and add a safety margin for transients and aging when specifying system limits.

Which thermal test gives the most actionable Rth number for system design?

Steady‑state thermal tests at the expected continuous Pd with monitored case and ambient yield practical Rth_ja targets. For pulsed operation, measure thermal impedance vs pulse width (Zth) to determine transient temperature swings; both tests together provide the Rth budget needed for heatsink and TIM selection.